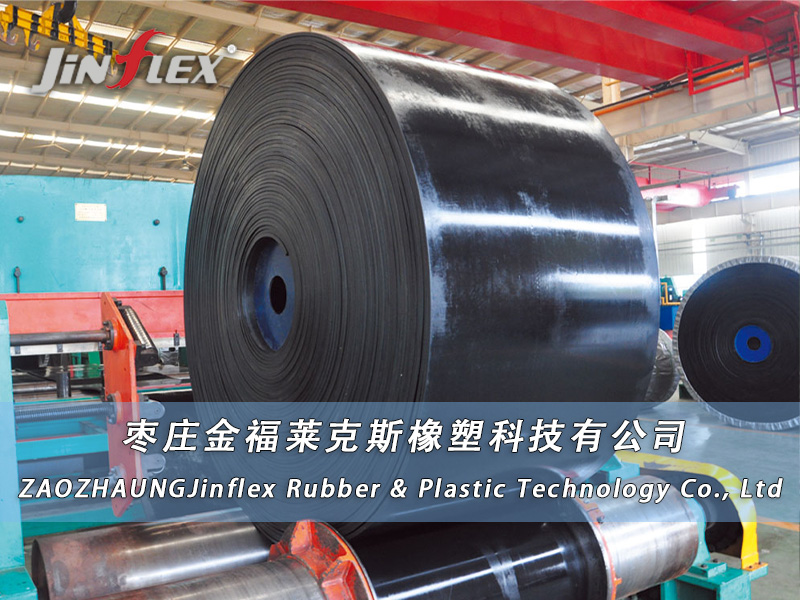

China Rubber Conveyor Belt | Acid and Alkali Resistant Conveyor Belt Supplier

Application of acid and alkali resistant conveyor belt:

Acid and alkali resistant conveyor belts are designed specifically for conveying materials in corrosive environments such as strong acids and alkalis, with excellent corrosion resistance and wear resistance. Widely used in industries such as chemical engineering, metallurgy, electroplating, and wastewater treatment.

Characteristics of acid and alkali resistant conveyor belt:

Excellent corrosion resistance: can be used for a long time in acidic and alkaline environments with pH values ranging from 2 to 14.

Good wear resistance: The covering adhesive is wear-resistant and extends its service life.

Tensile strength: The high-strength skeleton material ensures that the conveyor belt is not easily deformed under heavy loads.

Excellent temperature resistance: Suitable for temperatures ranging from -10 ° C to 120 ° C.

Application fields of acid and alkali resistant conveyor belts:

Chemical industry: transporting corrosive chemicals such as acids, alkalis, salts, etc.

Metallurgical industry: transporting corrosive materials such as ores and slag.

Electroplating industry: transporting electroplating solution, pickling solution, etc.

Wastewater treatment: transporting sludge and wastewater containing acid and alkali.

Reasons for choosing us:

Zaozhuang Jinflex Rubber Technology Co., Ltd. has been a Chinese rubber conveyor belt manufacturer specializing in the research and production of rubber products for 50 years. Produced strictly in accordance with international standards such as ISO, DIN, etc., the product quality has undergone rigorous testing and meets industry requirements. Provide various specifications and models of acid and alkali resistant conveyor belts to meet the needs of different industries and working conditions.

If you want to learn more about conveyor belts, please leave a comment or contact us directly via email“ [email protected] ”