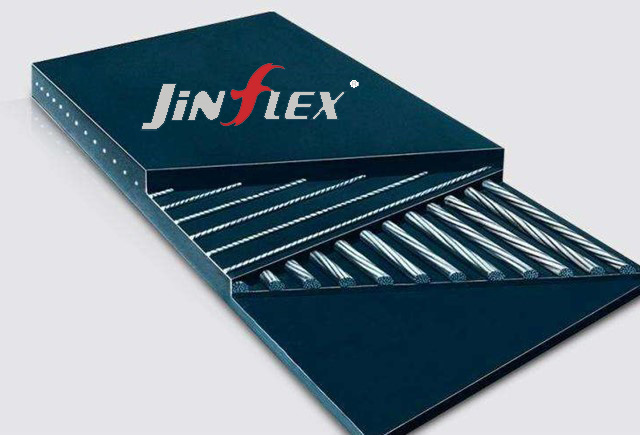

What other secrets of steel cord conveyor belt you don't know

The reason why the rubber layer of steel cord conveyor belt has good adhesion is mainly attributed to the following key factors:

1. Rubber quality

Rationality of formula: A reasonable formula can ensure that the rubber and the steel wire rope have sufficient chemical reaction and improve the bonding strength.

Impurity and bubble control: The presence of impurities and bubbles should be strictly controlled during the production process to ensure the purity of the rubber.

2. Process parameters

Appropriate vulcanization temperature: Use appropriate vulcanization temperature to improve the bonding strength. Vulcanization pressure: The pressure distribution during the vulcanization process should be uniform to ensure sufficient contact between the rubber and the steel wire rope. Insufficient pressure will reduce the contact area and thus reduce the bonding strength.

Reasonable vulcanization time: Too long vulcanization time may cause aging of the rubber, while too short time may lead to incomplete vulcanization.

3. Operation skills

Uniformity of glue application: The operator should ensure that the rubber is evenly applied during the glue application process to avoid a decrease in bonding strength due to a lack of sufficient rubber in some areas.

Correct placement of the wire rope: The wire rope should be placed correctly to avoid stress concentration during the vulcanization process, which affects the bonding strength.

4. Surface treatment of wire rope

During the production process, the wire rope should be strictly surface treated, including the presence of oil, rust or other contaminants on the surface to ensure good adhesion with the rubber.

In summary, the good adhesion of the rubber layer of the wire rope core conveyor belt is the result of the combined effect of multiple factors. In the actual production process, these factors should be strictly controlled to ensure the performance and service life of the conveyor belt.

Zaozhuang Jinflex Rubber and Plastic Technology Co., Ltd. has passed ISO9001 certification. The conveyor belts we produce are waterproof, aging-resistant, not easy to break, and not easy to debond. The product quality is good and can adapt to various complex working environments.

Interested bosses are welcome to inquire on the official website!