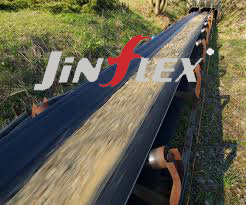

Why are cold-resistant conveyor belts cold-resistant?

Do you have such a question? Why can cold-resistant conveyor belts maintain excellent performance in cold environments? Let's take a look at the main reasons:

1. Special rubber formula

Use rubber materials with excellent cold resistance, such as nitrile rubber (NBR) and chloroprene rubber (CR). These rubber materials can still maintain good elasticity and flexibility at low temperatures and are not easy to harden or break.

2. Use of additives

Add cold-resistant additives such as anti-cold agents and plasticizers to the rubber formula. These additives can effectively improve the softness and cold resistance of rubber at low temperatures.

3. Fabric layer design

The fabric layer of the conveyor belt is usually made of materials with excellent cold resistance, such as canvas layer and polyester layer. These materials can maintain stable structure and strength at low temperatures.

4. Composite structure

Some cold-resistant conveyor belts use a multi-layer composite structure to combine different materials together to make the conveyor belt have better comprehensive performance in low temperature environments. This composite structure can effectively enhance the cold resistance and durability of the conveyor belt.

5. Advanced production technology

Zaozhuang Jinflex Rubber & Plastic Technology Co., Ltd. has been deeply involved in the field of conveyor belt production for 50 years, and has accumulated rich professional knowledge and technology. It has MA certification for all products. Its products have won the "National Only Quality Gold Award" and enjoy high popularity and good reputation.

If you are interested in our conveyor belts, please leave us a message or contact us directly by email "[email protected]".