Let's take you to understand the layered fabric core conveyor belt in one minute?

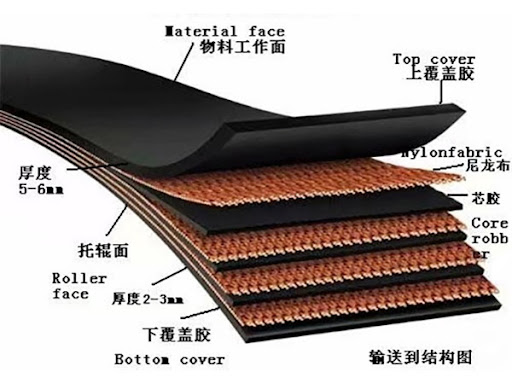

1. Covering rubber: upper covering rubber + lower covering rubber

The purpose of the covering rubber is to protect the fabric core from wear, impact, water and other harmful effects. According to different usage conditions, the covering rubber has ordinary and special types. The special type can meet special requirements such as wear resistance, oil resistance, heat resistance, flame retardancy, acid and alkali resistance.

2. Skeleton layer: polyester cloth (polyester + polyamide), nylon (nylon + nylon), canvas (cotton thread + cotton thread) The fabric core of the belt maintains the tension of the belt body and supports the strength of the structure, and bears almost all the loads during work.

3. Core rubber: It has good fabric adhesion, which makes the canvas tightly bonded together. It increases the flex life of the belt body and makes the connection between the cloth layers more elastic, so that the cloth layers will not separate when the belt is running.

Therefore, the structure of the layered fabric core conveyor belt mainly consists of upper covering rubber, lower covering rubber, skeleton layer, and core rubber. Zaozhuang jinflex Rubber & Plastic Technology Co., Ltd. is a professional manufacturer of conveyor belts with many years of experience. The layered fabric core conveyor belts we provide have excellent wear resistance, impact resistance and high strength, ensuring long-term durability.

If you want to know more about layered fabric core conveyor belts, please leave a message in the comment area or contact us directly by email "[email protected]"