Briefly describe the advantages of PVC solid woven conveyor belts

In modern industrial production, conveyor belts are indispensable logistics equipment, and their performance and quality are directly related to the efficiency and cost of the production line. Today, let’s talk about PVC solid woven conveyor belt and see how its structural features are unique compared with ordinary conveyor belts.

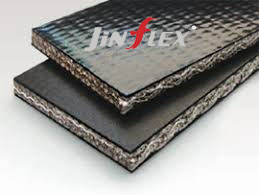

PVC solid woven conveyor belt, as the name suggests, its structure adopts solid weaving technology. This design makes the overall conveyor belt more sturdy and durable. Compared with ordinary conveyor belts, PVC solid woven conveyor belts are more compact in structure and less prone to breakage or wear, thus greatly extending their service life.

In addition to its structural advantages, PVC solid woven conveyor belts also have unique materials. It uses polyvinyl chloride (PVC) as the main material. This material is wear-resistant, corrosion-resistant, and weather-resistant, allowing the conveyor belt to maintain good performance in harsh working environments.

In addition, PVC solid woven conveyor belts also have better flexibility and stretch resistance. This feature makes the conveyor belt more stable during transportation and less prone to deviation or deformation, thus ensuring the smooth operation of the production line.

Compared with ordinary conveyor belts, PVC solid woven conveyor belts have obvious advantages in structure, material and performance. It is not only strong, durable, wear-resistant and corrosion-resistant, but also has better flexibility and stretch resistance. It is an indispensable logistics equipment in modern industrial production. If you are looking for a high-performance conveyor belt, you may wish to consider PVC solid woven conveyor belt, which will bring a more stable and efficient logistics experience to your production line.