Explore the various sizes of patterned conveyor belts

In modern production lines, patterned conveyor belts have become the first choice of many companies with their unique design and excellent performance. Today, let’s explore the various specifications of patterned conveyor belts and see how they help the production line run efficiently.

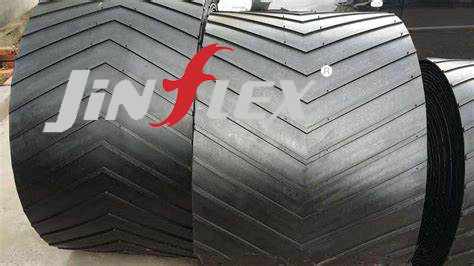

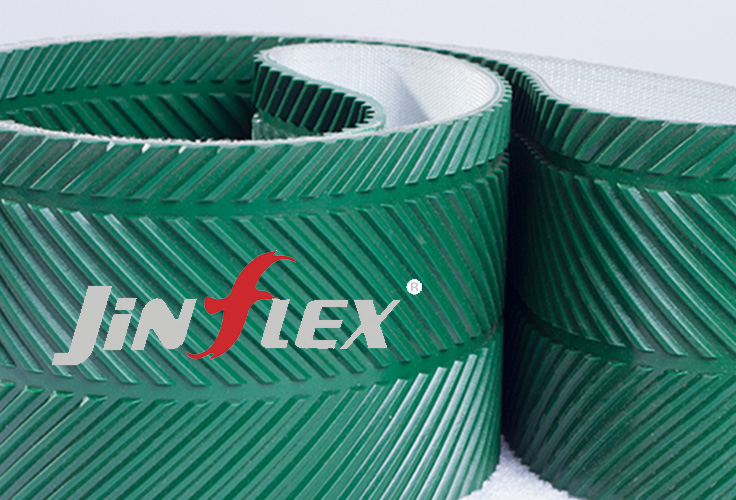

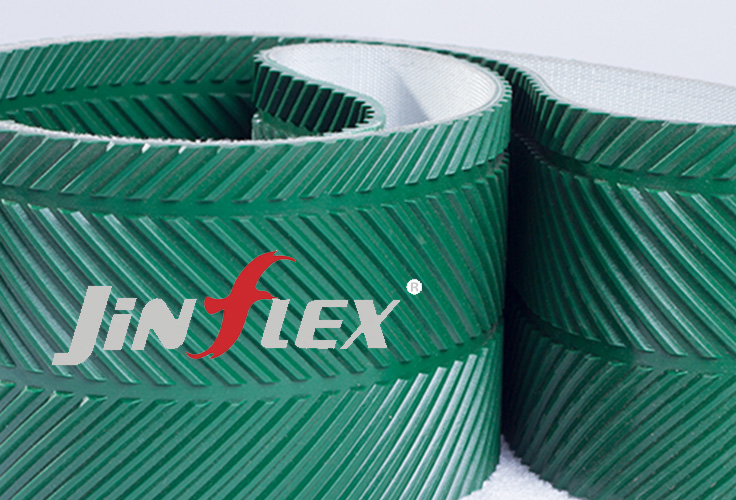

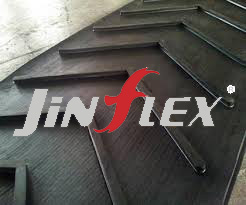

Pattern conveyor belt, as the name suggests, has patterns of various shapes and patterns on its surface. These pattern designs are not only beautiful, but more importantly, they can increase the friction between the conveyor belt and the material, preventing the material from slipping or accumulating during transportation. This characteristic makes the patterned conveyor belt perform well in scenarios such as inclined conveying and slippery material conveying.

When we talk about the specifications of pattern conveyor belts, the first thing to pay attention to is its width and length. The width determines the load-bearing capacity and stability of the conveyor belt, while the length is directly related to the conveying distance. Depending on the actual needs of the production line, patterned conveyor belts can be available in a variety of width and length specifications.

In addition to width and length, the material of the pattern conveyor belt is also an important consideration. Common materials include rubber, plastic, nylon, etc., each of which has its own characteristics, such as wear resistance, corrosion resistance, high temperature resistance, etc. Choosing the right material can ensure that the conveyor belt can maintain stable operation in harsh working environments.

In addition, the pattern designs of pattern conveyor belts are also diverse. Different pattern shapes and densities can adapt to different material characteristics and conveying needs. For example, for slippery materials, you can choose a conveyor belt with dense patterns and greater friction; while for heavy materials, you need to choose a conveyor belt with a strong structure and strong load-bearing capacity.

In short, the various specifications of patterned conveyor belts provide a strong guarantee for the efficient operation of the production line. When choosing pattern conveyor belts, we need to comprehensively consider the actual needs and choose the most suitable specifications and materials.