Patterned conveyor belts vs flame-retardant conveyor belts: Who is the leader in industrial conveying?

In busy industrial production lines, conveyor belts are like hard-working "porters", carrying the important task of transferring materials between various production links. Among the many types of conveyor belts, patterned conveyor belts and flame-retardant conveyor belts have become the focus of many companies because of their unique functions and advantages. So, who is the best between the two? Next, let’s delve into it together.

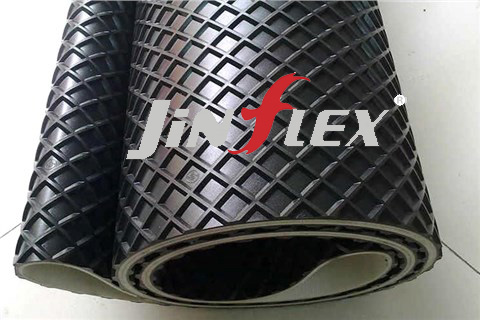

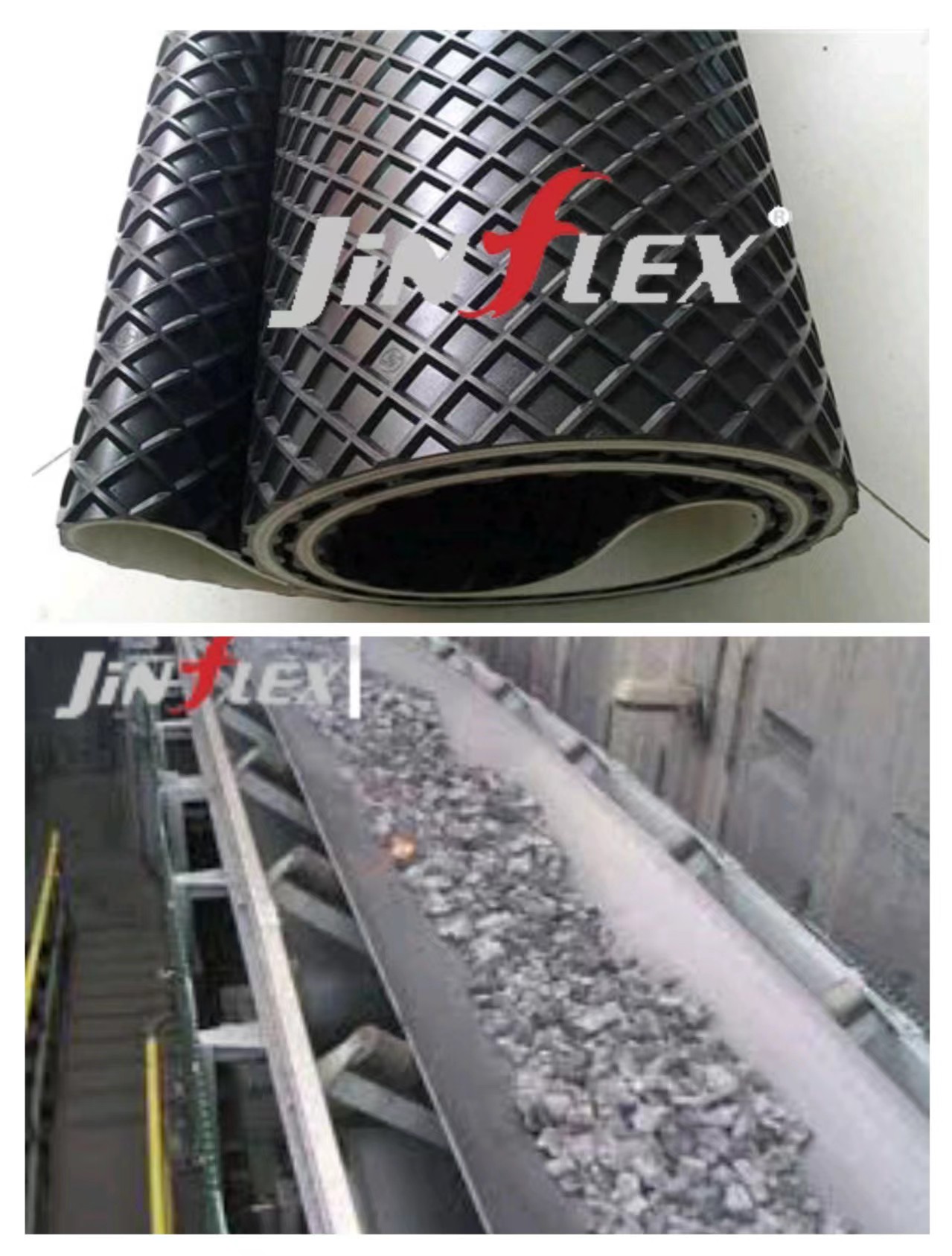

1. Pattern conveyor belt: synonymous with anti-skid and efficiency

Patterned conveyor belts have attracted much attention for their special pattern designs on their surfaces. This design not only increases the friction between the conveyor belt and the material, effectively preventing the material from sliding or sliding down during transportation, but also provides excellent anti-skid effects in wet, muddy or oily environments. In addition, the patterned conveyor belt can also form a stable "envelope" state, reduce material scattering and flying, and improve conveying efficiency. In the transportation of bulk materials, granular materials and block materials, pattern conveyor belts have demonstrated strong adaptability.

2. Flame-retardant conveyor belt: the guardian of safe production

Flame-retardant conveyor belts are popular for their excellent flame-retardant properties. In flammable and explosive production environments, flame-retardant conveyor belts can quickly self-extinguish when exposed to fire sources, effectively curbing the spread of fire and ensuring production safety. In addition, flame-retardant conveyor belts also use environmentally friendly materials and green production processes to reduce environmental pollution and damage. In coal, electric power, chemical and other industries, flame-retardant conveyor belts have been widely used and have become a powerful assistant for enterprise safety production.

3. Who is the best?

So, who is the best between patterned conveyor belts and flame-retardant conveyor belts? In fact, there is no absolute superiority or inferiority between the two, but each has its own characteristics and advantages. The choice of conveyor belt mainly depends on the specific needs of the enterprise and the production environment.

If the company needs to transport materials in a wet, muddy or oily environment, or needs to improve transportation efficiency and reduce material loss, then patterned conveyor belts are undoubtedly a better choice. And if the company is in a flammable and explosive production environment, or has higher environmental protection requirements, then flame-retardant conveyor belts will have more advantages.

Therefore, when selecting conveyor belts, companies should comprehensively consider their own production needs, environmental characteristics, and safety requirements to select the most suitable conveyor belt type. Only in this way can we ensure the stable operation of the production line, improve production efficiency, reduce production costs, and bring greater economic and social benefits to the enterprise.