Fabric core and wire rope core conveyor belts: the ideal partner for industrial conveying

In fast-paced modern industrial production, conveyor belts are indispensable "conveyors". Among the many options, fabric core and steel rope core conveyor belts have become the preferred partners for industrial conveying due to their unique advantages.

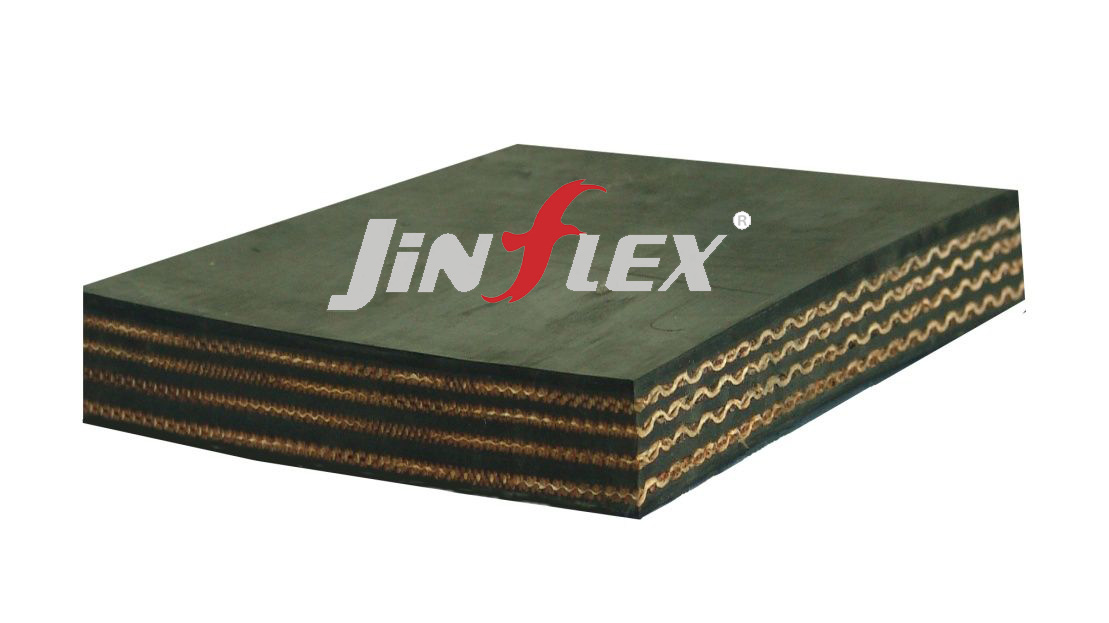

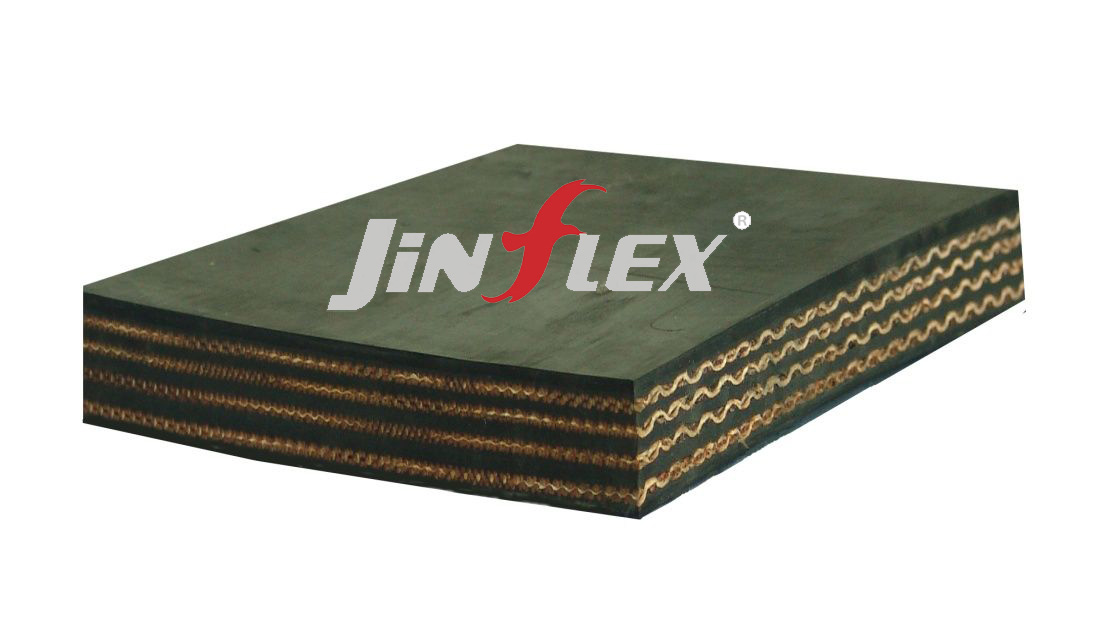

Fabric Core Conveyor Belts: Light and versatile, adaptable

Fabric-core conveyor belts, with their lightweight texture and excellent flexibility, perform well in situations where conveyor paths need to be changed frequently. Whether it is a complex production line layout or temporary changes in material flow requirements, it can easily handle it and ensure stable and efficient delivery of materials.

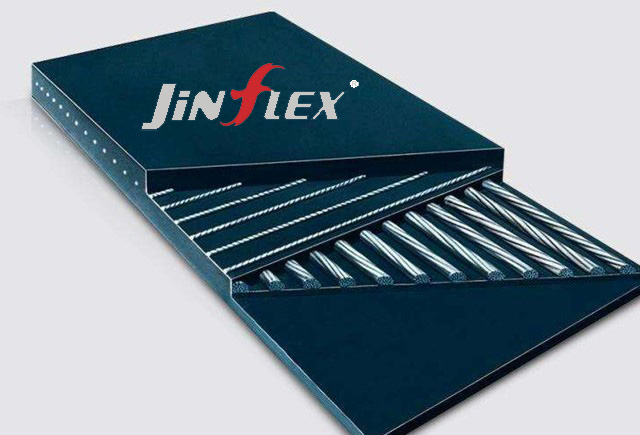

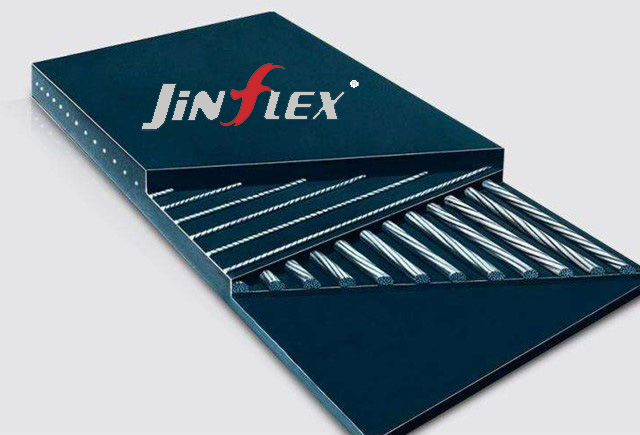

Steel rope core conveyor belt: tough and stable, worry-free load-bearing

Steel cord conveyor belts have won praise for their tough load-bearing capacity and stability. In heavy industrial fields, such as mines and ports, it needs to cope with long-distance and large-tonnage transportation tasks. Steel cord conveyor belts provide a solid guarantee for production in these fields with their excellent strength and reliability.

Complementary advantages and jointly build an efficient transportation system

Fabric core and steel rope core conveyor belts have their own characteristics and complement each other. The former is light and versatile, while the latter is tough and stable. Together they form an efficient and stable industrial conveying system. Enterprises can flexibly choose suitable conveyor belt products according to their own needs to ensure the smooth operation of the production line.

In short, fabric core and steel wire core conveyor belts, as the preferred partner for industrial transportation, will continue to provide strong support for industrial production. In the future, they will continue to play an important role in promoting the efficient development of industrial production.