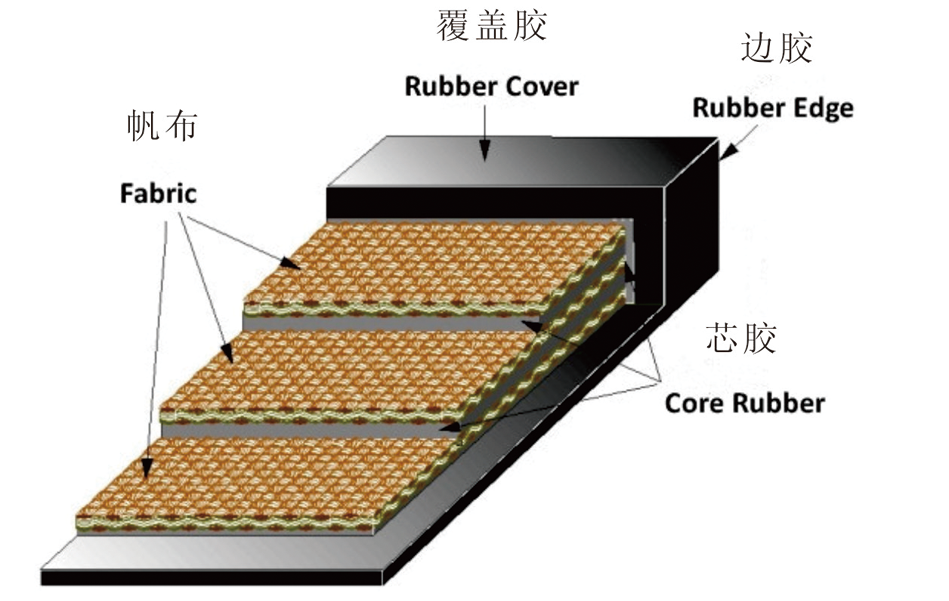

Multi-ply Fabric Conveyor Belt

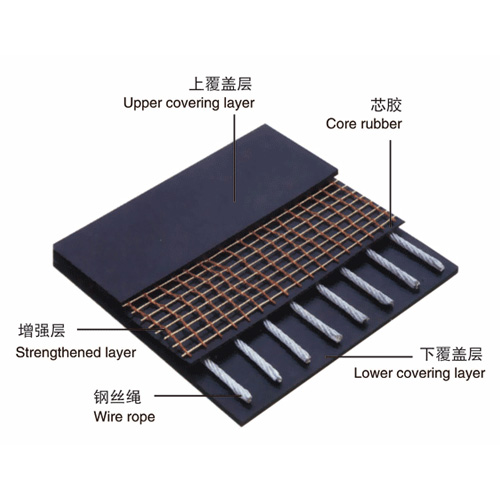

Construction:

Rubber Cover: top rubber cover + bottom rubber cover

Rubber cover is designed to protect the carcass from abrasion, impact, water and other injurious influence. According to different applications, there are general and special types. The special types can meet special requirements of abrasion resistant, oil resistant, heat resistant, flame resistant, and acid & alkali resistant, etc.

Carcass: EP (polyester + polyimide), NN (nylon + nylon), CC (cotton + cotton)

Carcass of the belt maintains belt tension and supplies structural strength, it undertakes almost all load in work.

Core Rubber: Has good fabric adhesion properties, which makes the fabrics bond tight. Can increase flex life and create a more elastic link, so that fabrics flex without separation when belt under working.

Advantage:

Excellent adhesion to rubber

High impact resistant

Low elongation

High modulus

Good flexibility & Good troughability

It is suitable for long distance, heavy load and high speed transportation of materials.

Application:

Cement, concrete plants

Quarry, sandpits

Coal, mining

Steel industry, heating and power station

Garbage incineration plants

Recycling, compost industry

Mineral processing plants

Road construction machinery, etc

Reference Specification

Fabric Type | Ply Strength (N/mm) | Ply Thickness (mm) | Cover Thickness (mm) | No. of Ply | Width Range (mm) | |

Top Rubber | Bottom Rubber | |||||

EP/NN100 | 100 | 0.75 | 3

4.5

6 | 1.5

3

6 | 2~8 | 300-2200 |

EP/NN 125 | 125 | 0.75 | ||||

EP/NN 150 | 150 | 0.85 | ||||

EP/NN 200 | 200 | 1.00 | ||||

EP/NN 250 | 250 | 1.20 | ||||

EP/NN 300 | 300 | 1.35 | ||||

EP/NN 400 | 400 | 1.65 | ||||

CC56 | 56 | 1.10 | ||||

CC70 | 70 | 1.00 | ||||